FORGED

FORGED

Couldn't load pickup availability

View full details

Knifemaking has always been an immensely popular hobby in the USA, even before the TV series “Forged in Fire” increased its popularity exponentially. But how does one begin this hobby without taking a course? Paul White’s highly praised book, FORGED, is an answer.

“This book is a must read for up-and-coming knifemakers.” – Lee Crawford, Professional knifemaker and winner of the Naval competition in TV’s “Forged in Fire” in the tournament of the Military Branches..

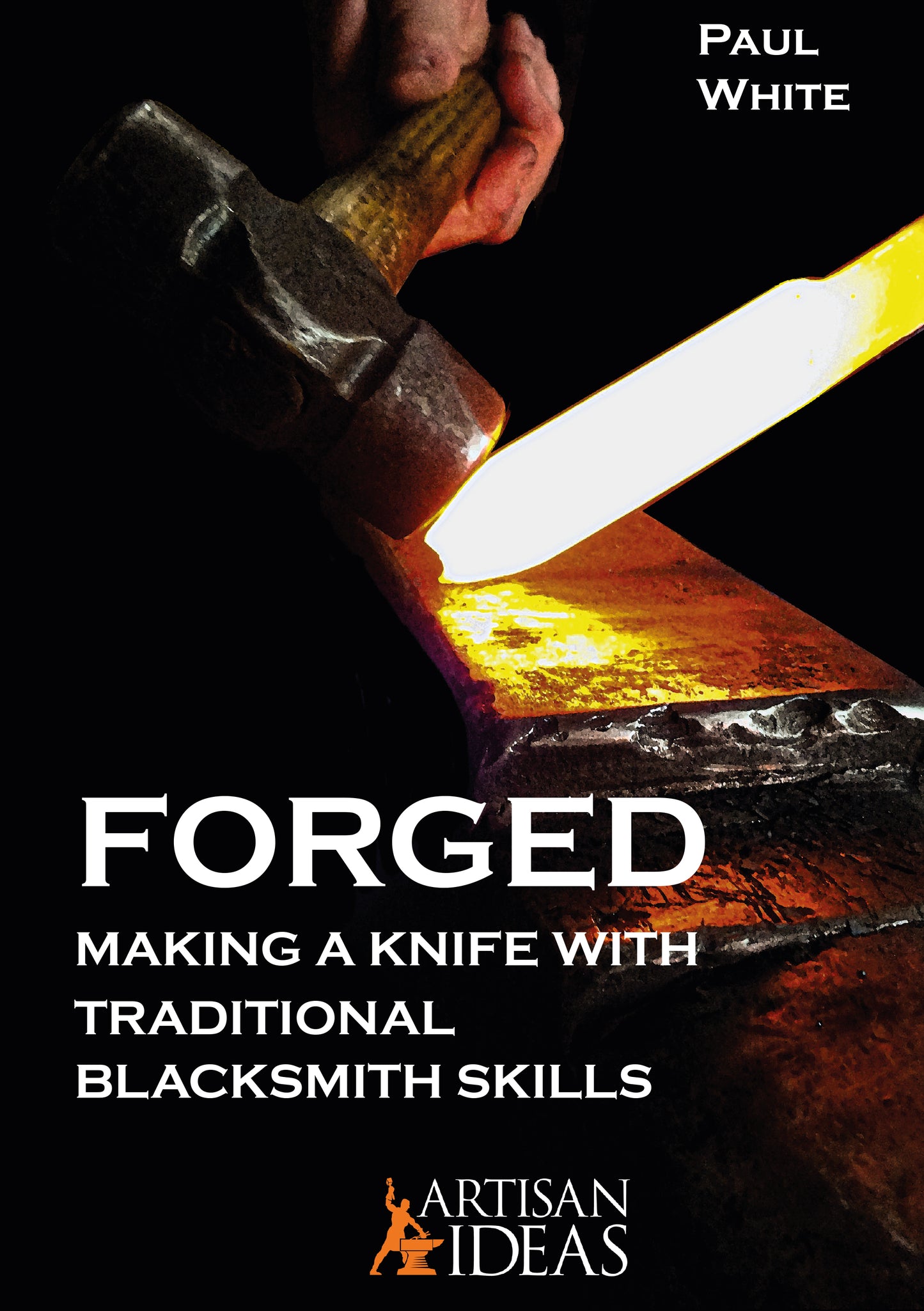

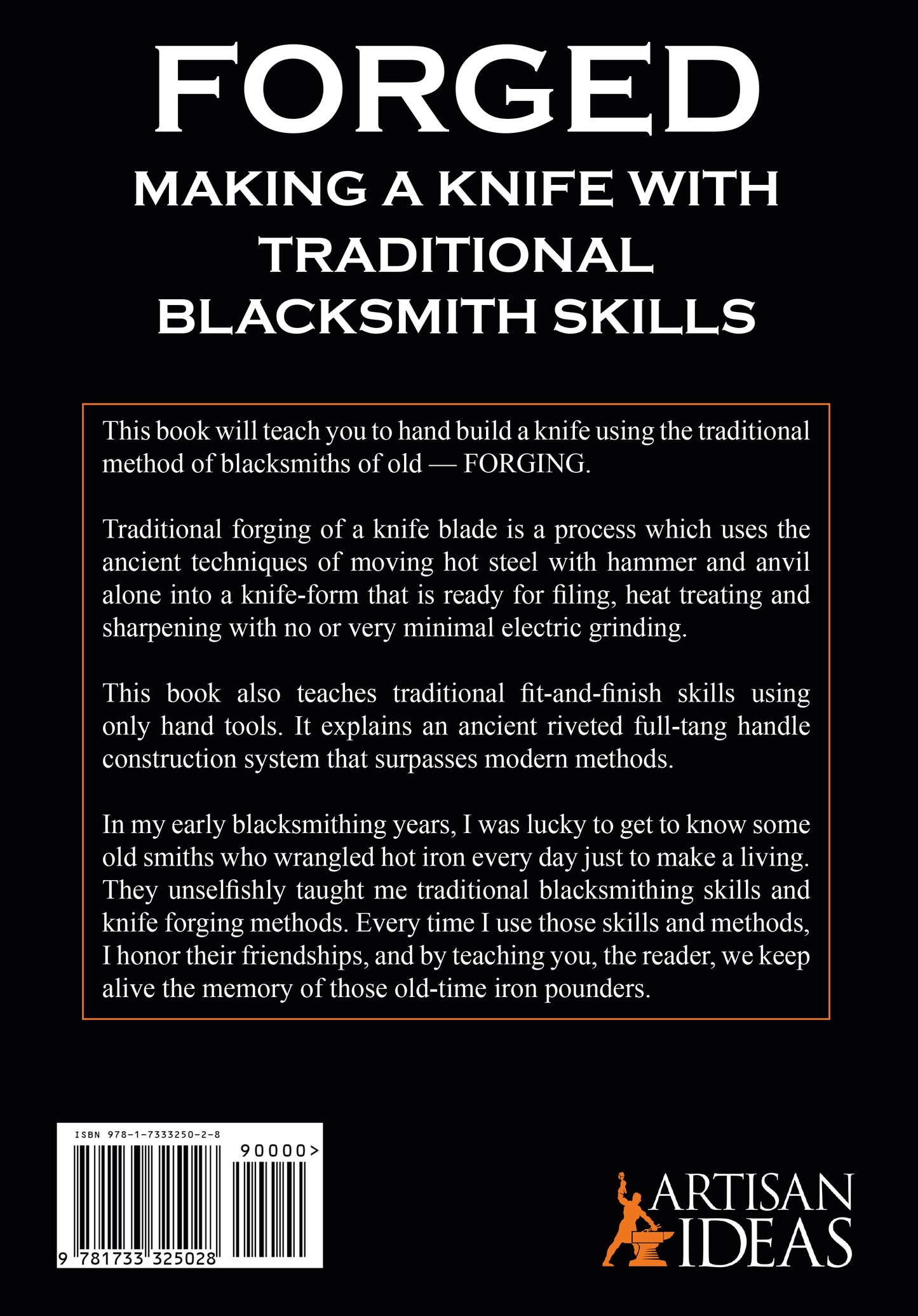

This book will teach you to hand build a knife using the traditional method of blacksmiths of old — FORGING.

Traditional forging of a knife blade is a process which uses the ancient techniques of moving hot steel with hammer and anvil alone into a knife-form that is ready for filing, heat treating and sharpening with no or very minimal electric grinding.

This book also teaches traditional fit-and-finish skills using only hand tools. It explains an ancient riveted full-tang handle construction system that surpasses modern methods.

In the author's words; "In my early blacksmithing years, I was lucky to get to know some old smiths who wrangled hot iron every day just to make a living. They unselfishly taught me traditional blacksmithing skills and knife forging methods. Every time I use those skills and methods, I honor their friendships, and by teaching you, the reader, we keep alive the memory of those old-time iro- pounders."

Paul White has been a blacksmith for over forty years. The smith who taught Paul to make his frontier style blade was Gus Marie of Brownsville, Illinois. Gus simply called his blade a work knife and so does Paul. The knife industry romanticizes this blade style by calling it a “Frontier” or “Bush Knife”. Gus was the last of an unbroken chain of blacksmiths, originally from France, who came to the Colonies before the American Revolution.

Paul’s other early mentors were Evan Cooper, an original cowboy from Utah that shod his own horses, made his own knives and branding irons, and repaired his own wagons; a real “throwback” kind of guy. The Deal brothers, Jim and Ben, both blacksmiths of Murphysboro Illinois, trained as rural smiths at Tuskegee College after the first Great War. They allowed Paul to “hang around their shop” helping out. Paul was also proud to have worked with Daryl Meier and Brent Kington of Southern Illinois University. Both men ushered in this modern era of blacksmithing and pattern-welded steel that we all enjoy. They too were an early and significant influence on Paul’s traditional training and approach to blacksmithing. Paul has treasured his friendships with these “old” smiths as much as the lessons they taught. Relocating to Northern Illinois in 1978 Paul was instrumental in establishing, equipping, teaching and demonstrating at the smith shop at Midway Village Museum in Rockford, Illinois. For many years he taught classes in general blacksmithing, Colonial hardware and, of course, knife making. He now limits his teaching to individual smiths seeking that traditional approach to blacksmithing passed-on to him from those legendary smiths of the last century. He has learned what works and what doesn’t in teaching others to build a knife. He has captured those old-time secrets in this book and wants to see other smiths enjoy traditional blacksmithing as much as he does. Paul is an old-time guy, teaching an old-time skill to make an old-time tool.

Review text

“In ‘Forged: Making a Knife with Traditional Blacksmith Skills’ author Paul White sets out to teach exactly that; how to forge a frontier knife, start to finish, using nothing but hammer, anvil, files, and other traditional hand tools. A working blacksmith for over 40 years, and a teacher of traditional blacksmithing for much of that time, White is well-qualified to write this book. With sections on blacksmithing history and the history of steel, the general use of blacksmithing tools, and the selection of suitable knife steel (and why); he then moves into an extremely detailed, step-by-step guide to building the 5-inch utility blade that he refers to as the "frontier knife." I highly recommend this book for a beginner, or, for a blacksmith who perhaps hasn't done much work with high-carbon knife steel but would like to learn. It is also an excellent read for anyone simply interested in knowing a bit of the history of traditional bladesmithing, and who wants to understand the processes involved. The author is very detailed, and I believe it would be impossible for even the most experienced smith to read this book without gleaning at least a few new tidbits.”

Review text

“One of the first observations is the quantity and quality of the photographs and drawings, easy to see what is going on and well reproduced in copy. Another feature is inserts scattered throughout the text titled: Tip, Note, Blacksmith Secret, each revealing a tidbit of information added in here and there to emphasize something in the text. The history of iron and steel is brief but accurate as is the explanation of the why and how of heat treating imparting enough information to make a usable blade without a lot of unnecessary scientific speak. The knife explained here is easily made without any expensive power tools, just hand tools. All in all I found this book easy to read and understand and a student of smithing with a bit of hammer skills under their belt should not have much problem producing a usable knife.”

Review text

“In 'Forged: Making a Knife with Traditional Blacksmith Skills', Paul White sets out to teach the beginner bladesmith how to forge a basic working knife, which he calls a frontier knife. He uses a low tech, by-hand method that he was taught by his mentors. He's organized and explains well in plain English how to accomplish this 12-15 hour project. The book starts with basic metallurgy, anatomy and geometry of a knife, hammer selection (rounding hammer recommended), and using the vise to straighten the handle and blade (heat and lock technique). There's a good section on the types of mistakes students make and how to fix them - including how he deals with the fishmouth seen in the cover photo. 'Forged' ends with instructions on heat treating, riveting a wood scale handle, polishing and sharpening. I think that the heat treating chapter is the best part of the book; explaining a confusing topic (to a beginner) in an organized, common sense way. There's information on annealing, normalizing, hardening, edge quenching, and several tempering techniques. Forged fills a niche; the beginner or intermediate smith who wants to get beyond stock removal and make forged knives using only hand tools. If you're in this category, read 'Forged'”.

Review text

“Concise and simplified instructions along with the illustrations made for an informative and easy to follow plan. The injection of tips kept me wanting to read and learn more. The simple, yet effective layout of information and instruction made this an enjoyable read. A great source of tips and tricks for any bladesmith from start to finish. This book is a must read for up-and-coming bladesmiths. It inspired me to try my hand at an all-traditional knife build in the future.”

Review text

Synopsis: With the publication of "FORGED: Making a Knife with Traditional Blacksmith Skills", blacksmithing expert Paul White will teach you, step-by-step, how to hand build a knife using the traditional method of blacksmiths of old

Reviewer's Note: Paul White has been a blacksmith for over forty years. The smith who taught Paul to make his frontier style blade was Gus Marie of Brownsville, Illinois. Gus was the last of an unbroken chain of blacksmiths, originally from France, who came to the Colonies before the American Revolution. Relocating to Northern Illinois in 1978 Paul was instrumental in establishing, equipping, teaching and demonstrating at the smith shop at Midway Village Museum in Rockford, Illinois. For many years he taught classes in general blacksmithing, Colonial hardware and, of course, knife making. He now limits his teaching to individual smiths seeking that traditional approach to blacksmithing passed-on to him from those legendary smiths of the last century.

Review: Effectively and profusely illustrated with full color photography throughout, "FORGED: Making a Knife with Traditional Blacksmith Skills" offers a complete course of DIY instruction that is fully 'user friendly' in organization and presentation. Of special appeal and value to readers with an interest in weapon smithing, metal working and folkcrafts, "FORGED: Making a Knife with Traditional Blacksmith Skills" is especially and unreservedly recommended for personal, professional, community, and college/university library Blacksmithing collections and supplemental curriculum studies lists. It should be noted for aspiring or professional metalworkers and blacksmiths that "FORGED: Making a Knife with Traditional Blacksmith Skills" is also readily available in a digital book format (Kindle, $9.99).In the author's words; "In my early blacksmithing years, I was lucky to get to know some old smiths who wrangled hot iron every day just to make a living. They unselfishly taught me traditional blacksmithing skills and knife forging methods. Every time I use those skills and methods, I honor their friendships, and by teaching you, the reader, we keep alive the memory of those old-time iron pounders."

Traditional forging of a knife blade is a process which uses the ancient techniques of moving hot steel with hammer and anvil alone into a knife-form that is ready for filing, heat treating and sharpening with no or very minimal electric grinding.

"FORGED" teaches traditional fit-and-finish skills using only hand tools and also explains an ancient riveted full-tang handle construction system that surpasses modern methods.